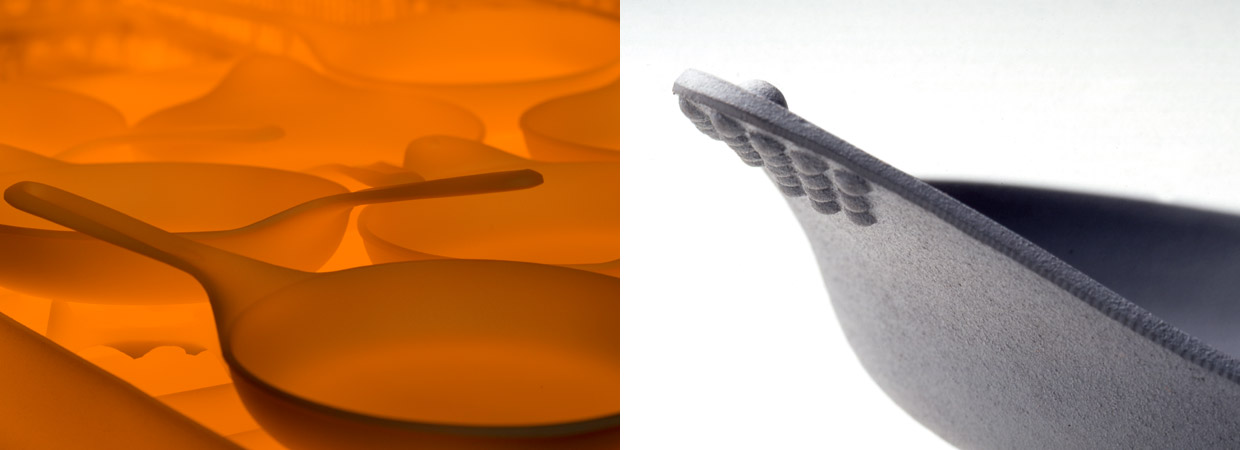

OIGEN quality is

about more than

just functionality

and design.

Quality

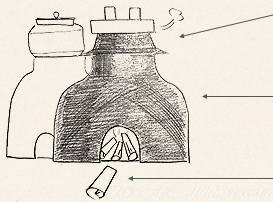

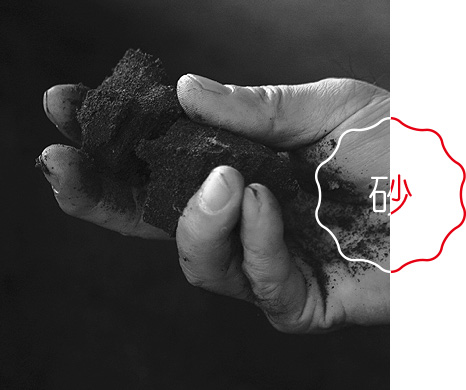

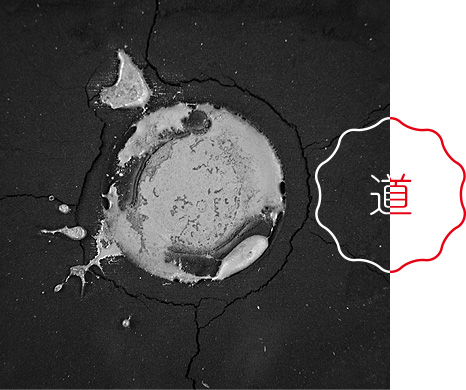

Through regular use, these iron instruments crafted by hand in this harsh climate become invaluable lifelong partners, backed by the OIGEN quality assurance.

OIGEN